Well-Safe Solutions Ltd is the industry’s first Tier 1 capable contractor and energy transition specialist focused on well decommissioning and carbon capture, utilisation, and storage. Phil Milton, CEO, discusses a groundbreaking approach to this fast-growing part of the global energy sector.

DEDICATED TO DECOMMISSIONING

While decommissioning in the UK continues to grow in economic and sociopolitical importance, there’s still a lot of work to be done to manage the country’s petroleum legacy.

Approximately nine percent of platforms in the UK Continental Shelf (UKCS), one of the most tightly regulated and safety-conscious mature basins in the world, have been decommissioned to date.

In the coming years, several more UKCS assets are set to move into the decommissioning phase, which requires different methodologies to those needed for drilling.

The industry therefore requires a dedicated well decommissioning specialist – this is where Well-Safe Solutions Ltd (Well-Safe Solutions) comes in.

“We’re the only contractor that purely focuses on well decommissioning,” acclaims Phil Milton, CEO.

As onshore and offshore oil and gas wells reach the end of their lifecycle, it is a legal requirement that they are decommissioned.

Well-Safe Solutions works with the energy industry to safely, efficiently, and permanently close wells, ensuring no harm to the environment.

Since being founded in 2017, the company’s experience to date has shown that decommissioning requirements are far from one size fits all.

However, Well-Safe Solutions’ ‘building block approach’ enables clients to piece together a bespoke decommissioning package that is scalable and tailor-made to suit distinct project needs.

“We can scale the number of services that we provide to our customers according to their requirements,” Milton tells us.

VERSATILE FLEET

Well-Safe Solutions offers complete, fully integrated well plug and abandonment (P&A) services, from front-end engineering and design through to project management and execution, using its own bespoke assets.

The company’s three decommissioning rigs – Well-Safe Guardian, Well-Safe Defender, and Well-Safe Protector – comprise its robust, high-performing fleet.

“We’ve got two semi-submersible drilling rigs and a jack-up drilling rig that have all been repurposed for well decommissioning and carbon capture and storage (CCS) drilling,” outlines Milton.

The Well-Safe Guardian, a highly efficient and experienced Earl & Wright 700 series midwater semi-submersible unit, has a strong track record in multi-well, multi-operator campaigns and is complemented by the Well-Safe Defender, an enhanced pacesetter semi-submersible asset.

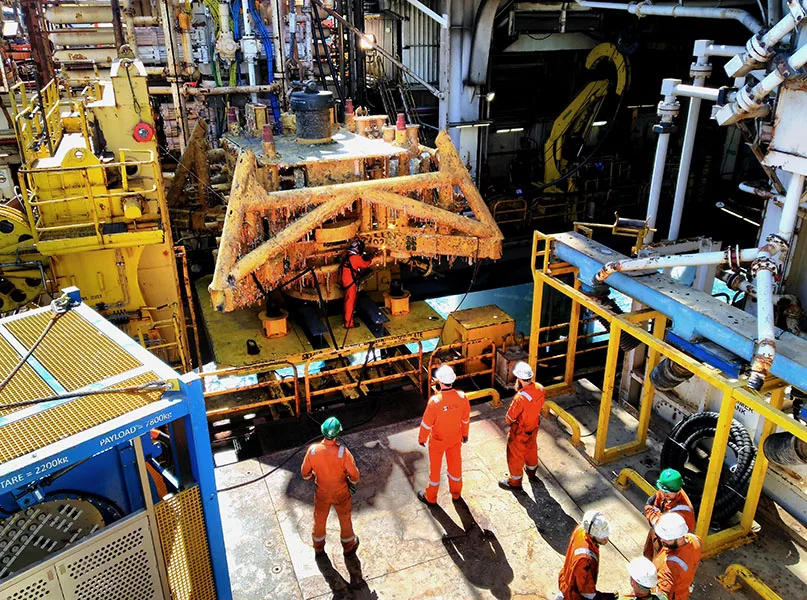

A saturation diving system has been manufactured and installed on the Well-Safe Guardian, enabling safe access to legacy subsea wellheads and Christmas tree systems that were originally designed for diver intervention. This makes the Well-Safe Guardian the sole North Sea asset of its type to feature a saturation diving system.

“It gives us the ability to deploy divers directly from the rig while we’re working on old wells that were put in place using divers prior to the existence of remote-operated vehicles,” Milton explains.

The system is a cost-effective, flexible alternative to the industry standard, which typically involves a light well intervention vessel used to plug and lubricate the well before completing decommissioning operations with a standard semi-submersible mobile offshore drilling unit.

This single-asset solution offers an alternative to the conventional approach and does not require multiple vessel mobilisations and demobilisations, which lowers operating costs, minimises the risk of weather-related disruption, and boosts overall project efficiency.

“Instead of mobilising multiple assets, we can do it from a single asset using the Well-Safe Guardian. Not only does this offer significant cost savings for our customers, but it also reduces fuel consumption and emissions, so it’s a very unique offering,” prides Milton.

The Well-Safe Protector, meanwhile, is a heavy-duty jack-up rig with an extensive, enviable history in the North Sea.

It boasts a rig-owned platform interface system with power, water, and air tie-ins, as well as a large amount of deck space for tubing, casing, and conductor recovery.

“This is a really unique asset in terms of some of the modifications that were done both prior and subsequent to us buying it, which have made it an optimal solution for wells that need to be re-entered with a jack-up,” Milton notes.

“We’re still in the early stages of well decommissioning, and it’s exciting to address some of the challenges that are out there”

Phil Milton, CEO, Well-Safe Solutions Ltd

ATTRACTING TALENT

Coupled with the company’s 430+ highly-trained personnel, the technical attributes of these three assets ensure increased operational safety and efficiency for decommissioning campaigns.

“We’ve got well engineering, project management, and subsurface capabilities. Our team determines how we decommission and safely cap these wells,” Milton informs us.

Ultimately, well decommissioning and CCS are global requirements, and there are many decades of work ahead to be done by the likes of Well-Safe Solutions.

Indeed, the international cost of decommissioning is expected to reach USD$200 billion over the next 20 years, approximately half of which is forecast to be spent on well abandonment alone.

In recognition of this critical need, the company continues to attract the necessary new talent both in the business and the industry as a whole.

The newly launched Well-Safe Excelerator programme, for example, aims to build lasting careers and deliver the decommissioning expertise required to support the global energy transition, combining bespoke training with practical experience.

“Well-Safe Excelerator looks to bring in apprentices, graduates, and ex-armed forces personnel to try and attract new talent into the industry and demonstrate that there’s actually a career in well decommissioning for people who want to help deliver the energy transition,” highlights Milton.

By decommissioning legacy oil and gas wells and repurposing reservoirs for CCS, Well-Safe Solutions is trying to address the net zero energy transition.

“The company was launched specifically for that purpose; for us, it’s about effectively helping to deliver it,” states Milton.

“Clearly, the net zero transition has to consist of the removal of the old wells and infrastructure that were part of the oil and gas phase.”

The capabilities and skillsets that Well-Safe Solutions has mean it is perfectly placed to work with customers to determine the most efficient way to remove old well infrastructure and either drill or, when possible, repurpose wells for CCS.

“It’s a key element, and I think the more that you bring those elements together, the more you can optimise cost efficiencies and the environmental impact of carrying out those different scopes,” Milton says.

“Clearly, the net zero transition has to consist of the removal of the old wells and infrastructure that were part of the oil and gas phase”

Phil Milton, CEO, Well-Safe Solutions Ltd

GROWTH JOURNEY

Well-Safe Solutions is focused on its environmental, social, and governance (ESG) credentials, and recently achieved ISO 50001 accreditation as part of the ESG pathway it started around 18 months ago.

As well as looking after the environment, the company prioritises the safety of its employees.

“Looking after our staff is fundamental to the success of the business. The same applies to partners, suppliers, and customers; we’ve never lost sight of the fact that everyone plays an important role in Well-Safe Solutions’ success,” emphasises Milton.

Equally, another of the company’s focus areas is international expansion. The idea for Well-Safe Solutions was always to build its foundations in the UK, which is a highly regulated environment, demonstrate that the model could be deployed safely and efficiently, and then look to export it internationally.

Operating from its Scottish headquarters in Aberdeen, the company recently opened an office in Perth, Western Australia as it targets adding further assets to the business.

“Moving into the Australian market last year was the beginning of our international growth journey, and now we’re very focused on continuing and accelerating into the global market,” Milton specifies.

“Australia and Southeast Asia are key areas, so there are several opportunities and future investments that we’re looking to pursue.”

As well as delivering the ongoing growth that has already been seen in these two regions, Well-Safe Solutions is likewise considering the possibility of an additional European office.

It is also seeking to grow and exploit opportunities in the European land market through onshore wells that need to be decommissioned and geothermal wells that may need to be drilled in the future.

“There are some ongoing discussions that I expect to progress through the course of this year and early into 2025,” outlines Milton.

These growth and investment opportunities reiterate that the Well-Safe Solutions model can be deployed and provide results for customers across the world, having an impact on their projects.