Across Europe, the Middle East, and Africa (EMEA), Orica is at the forefront of innovation, technology, and sustainability in the mining and infrastructure sectors. Victor Morales, Vice President of EMEA Mining, digs deep into developments across the region.

SUSTAINABLY MOBILISING THE EARTH’S RESOURCES

The story of one of the world’s leading mining and infrastructure solutions providers began more than 150 years ago.

Founded in June 1874 as a supplier of explosives to the Victorian goldfields in Australia, Orica proudly celebrated its sesquicentenary last year, an exciting milestone for the company.

This extensive heritage is a testament to Orica’s resilience, adaptability, and ability to thrive in a constantly evolving business landscape.

Its 150-year journey has also been one of transformation, as the company originally started out as Jones, Scott and Co. before it was bought by Nobel.

The organisation then went on to merge with Brunner Mond and Co., the United Alkali Company, and the British Dyestuffs Corporation to form Imperial Chemical Industries Plc (ICI Plc).

In 1928, Imperial Chemical Industries of Australia and New Zealand (ICI ANZ) was incorporated to acquire and coordinate the Australasian interests of ICI Plc, later becoming ICI Australia in 1971.

When ICI Plc divested its major shareholding in ICI Australia in 1997, a new independent Australasian company was formed, known since February 1998 as Orica.

The acquisition of ICI Plc’s global explosives interests began Orica’s transformation into a global business, one that has maintained its proud traditions of leadership, innovation, quality, and safety.

Orica has also grown to become one of the leading publicly-owned companies listed on the Australian Stock Exchange (ASX) over the course of 150 years.

Throughout 2024, the business recognised its landmark anniversary together with its people, partners, customers, and communities globally whilst taking the opportunity to reflect on its proud history and look towards the bright future of this iconic organisation.

A DYNAMIC AND DIVERSE REGION

Today, Orica employs a community of more than 12,500 engineers, scientists, technologists, operators, business specialists, and on-site crew around the world, supporting customers in surface and underground mines, quarries, construction, and oil and gas operations.

The business operates in over 100 countries worldwide, including numerous sites across the EMEA region, an extensive area that is incredibly dynamic and diverse with unique cultures and a wide range of mining commodities and segments.

The company’s commitment to excellence in the EMEA mining sector is unwavering as it is a key region within Orica’s global operations, with a diverse talent pool of approximately 2,000 staff members dedicated to delivering value and the best customer experience.

“We serve around 1,500 customers, ranging from large mining corporations to small and medium-sized enterprises (SMEs) in quarrying, construction, and infrastructure,” outlines Victor Morales, Vice President of EMEA Mining at Orica.

“What makes EMEA particularly inspiring is the opportunity to collaborate with talented individuals from across this vast and multicultural region, combining diversity, innovation, and meaningful contributions to the mining industry’s future.”

Orica’s solutions extend beyond blasting and integrate seamlessly into the entire value chain, from geological exploration and blast design to ore processing and addressing geotechnical challenges.

This comprehensive approach enables the company to support mining and infrastructure projects with innovative technologies and tailored services that drive efficiency and sustainability.

“Our talented teams thrive in challenging environments, developing and implementing unique solutions that address the entire value chain,” Morales acclaims.

Equally important is Orica’s dedication to creating value not only for customers, but also for the communities where it operates.

This holistic approach, powered by local expertise and cutting-edge technologies, reinforces the company’s position in EMEA as a global leader in mining and infrastructure solutions.

“What makes EMEA particularly inspiring is the opportunity to collaborate with talented individuals from across this vast and multicultural region, combining diversity, innovation, and meaningful contributions to the mining industry’s future”

Victor Morales, Vice President of EMEA Mining, Orica

SUSTAINABLE OPERATIONS

Sustainability continues to be a core focus of the industry as organisations work to decarbonise their operations and supply chains.

Areas such as Africa, Central Asia, the Middle East, and Southern and Eastern Europe are growing fast and rapidly evolving to play a pivotal role in supporting the global energy transition.

Demand for copper, nickel, and other future-facing commodities remains strong as the energy transition gains momentum. However, with the push towards a lower-carbon economy, there is expected to be a decline in thermal coal, which is crucial for meeting the energy needs of developing countries.

Sustainability is a key strategic component and integral to operations in EMEA and globally at Orica, whose purpose is to sustainably mobilise the earth’s resources and ambition is to achieve net zero emissions by 2050.

“My interest in mining grew as I recognised its critical role in supporting global sustainability, providing essential raw materials for the energy transition and critical minerals that are vital for modern society,” reflects Morales.

The company delivers smart, safe, and sustainable solutions for customers working in complex operating environments, playing its part in addressing climate challenges and supporting local communities.

Championing a more environmentally-friendly industry, responsibly managing its impact on society, and supporting the fair transition to a net zero economy is fundamental to Orica’s decision-making and the way it runs the business.

Indeed, sustainability is embedded in the company’s policies, business strategy, and practices as it pursues new opportunities, delivers on its commitments, and improves its performance.

Guided by its sustainability strategy, which is informed by the UN’s Sustainable Development Goals (SDGs), Orica collaborates with customers and other stakeholders to find solutions to the industry’s biggest challenges and move together towards a lower-carbon future.

Along with proactively engaging with a diverse range of stakeholders in EMEA and around the world, Orica undertakes periodic materiality assessments to understand the topics that matter most to them and inform its strategy, public sustainability targets, and external reporting.

The company is focused on mobilising the materials, metals, and minerals required to help the global economy grow and transition to net zero emissions, advancing technology and innovation across the value chain and accelerating its decarbonisation commitments.

ESSENTIAL MATERIALS

Orica is committed to securing the supply of critical raw materials for the mining industry, with the safe and reliable supply of ammonium nitrate (AN) another key component of its offering.

“As one of the world’s leading producers of AN for technical use, we operate five production facilities worldwide,” confirms Morales.

“We are also one of the main buyers of AN for technical use, especially for our operations in EMEA and Latin America, where we have long-term agreements to secure steady supply to our operations.”

In EMEA, Orica recently partnered with Fertiberia to execute the first blast using low-carbon technical ammonium nitrate (TAN) in June 2024 at the Canteras de Santullán quarry in Spain.

This innovative product, made with renewable hydrogen, marks a milestone in reducing the carbon footprint of blasting and mining operations, providing a more sustainable solution compared to conventional TAN.

The blast signifies a further step towards the decarbonisation of mining, a crucial sector for the energy transition due to its role in extracting copper and other essential industrial minerals, as it marked the first industrial-scale use of a sustainable, low-carbon explosive product.

Alongside AN, Orica also invests in the production of various essential materials such as sodium cyanide and other critical resources.

“This ongoing investment strategy ensures we can meet the growing demands of our customers whilst supporting the industry’s long-term sustainability,” Morales emphasises.

INNOVATIVE TECHNOLOGIES

The new mining and infrastructure projects driving the EMEA region evidently have a great focus on sustainability and efficiency, supported by the introduction of forward-thinking technologies.

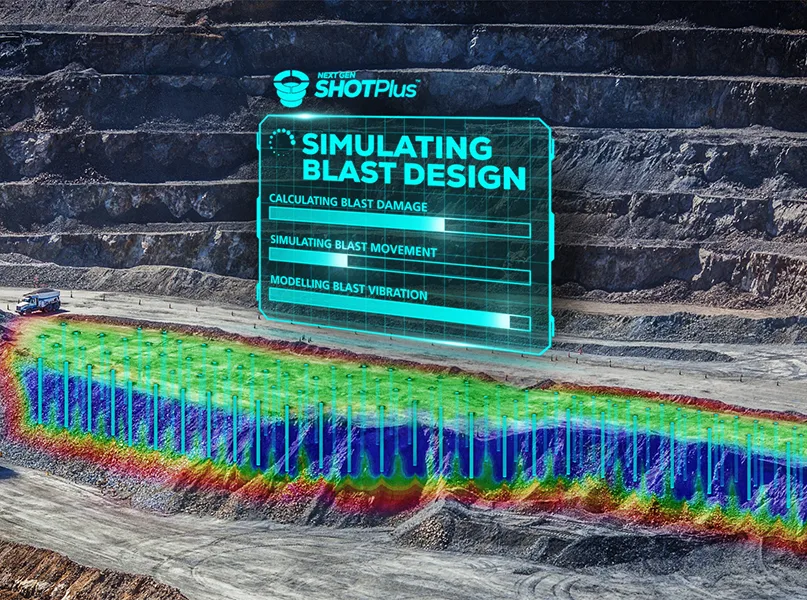

“We continue to innovate with groundbreaking solutions designed to enhance efficiency, safety, and sustainability in mining operations,” Morales states.

Orica has long been at the forefront of innovation in mining and infrastructure, helping to shape the industry through leading digital and automated technologies to create safer and more productive outcomes for customers.

Continuous innovation led by talented people and fuelled by collaboration with customers and industry and research partners to solve shared challenges has been at the heart of the company’s success over the past 150 years.

Innovation at Orica is defined by its pioneering spirit and key to addressing the significant global challenges faced by the mining industry, including sustainability, safety, efficiency, resource depletion, and social responsibility.

Finding ways to address these is therefore essential for the sustainable growth and development of the industry.

Committed to continuous technological investment, the company’s vision is to transform how drilling and blasting are used to unlock mining value.

“Our innovations reflect Orica’s dedication to providing cutting-edge, value-driven solutions for the evolving needs of the mining industry,” prides Morales.

In EMEA, the company has technology centres located in Gyttorp, Sweden and Troisdorf, Germany that specialise in non-electric (NE) initiation and electronic blasting systems (EBS), respectively.

These two regional sites complement Orica’s global technology centres in Australia, the US, Canada, and Singapore, as well as its Centre for Innovation and Collaboration in Chile.

“Together, Orica’s innovations improve safety, efficiency, sustainability, and operational flexibility in mining environments”

Victor Morales, Vice President of EMEA Mining, Orica

CIRCULAR SOLUTIONS

Orica is in a unique position to leverage its expertise in technology to create solutions that deliver positive socioeconomic and environmental contributions to customers and communities around the world through its business activities.

For example, the company is reducing environmental footprints by offering more sustainable solutions such as Exel™ Neo, which was launched in September 2023 and represents another step towards the company’s purpose.

The world’s first series of lead-free NE detonators, Exel™ Neo uses unique, proven non-primary explosives detonator (NPED) technology for the safe and reliable initiation of explosives.

“Exel™ Neo offers reliable and robust lead-free detonators for operations in challenging conditions,” Morales tells us.

Orica does not use lead or lead components in the manufacturing or production of Exel™ Neo detonators, but rather a safer and more sustainable lead-free formulation in Gyttorp, creating more eco-friendly products whilst maintaining the performance of its premium Exel™ range.

Exel™ Neo detonators are designed for use in civil infrastructure, as well as surface and underground mining operations.

The technology is manufactured close to Orica’s customer base in Europe and is currently available in the EMEA region.

The first Exel™ Neo detonators were shipped from its state-of-the-art Swedish production facility in November 2023 to address the need for more sustainable initiation systems in the market.

Orica’s NE manufacturing and supply network is expanding, with capability and capacity uplifts at a number of sites.

New equipment and processes have solidified multiple export hubs, improving the safety, efficiency, reliability, and security of shipping components to the company’s assembly plants.

AUTOMATED PROCESSING

Along with Exel™ Neo, Orica is also lowering environmental footprints through solutions such as Cyclo™, an automated processing system that enables used oil from heavy machinery to be recycled directly on-site and transformed into raw materials.

The proven technology offers efficient processing and quality output that matches the standard required for the manufacturing of emulsion explosives.

Designed to support remote operations where Orica’s site-based emulsion plants are available, Cyclo™ delivers several environmental and commercial benefits for surface metal and coal mining.

For example, up to 1,000 litres (L) of used oil can be processed per hour by the fully containerised and automated system, associated used oil disposal costs and risks can be lowered, whilst annual diesel consumption in the production of bulk explosives can be reduced by up to an estimated 800,000L per site.

Cyclo™ additionally reduces logistical risks as it removes the need for off-site disposal and truck movements through local communities and ensures finished product quality is maintained to the standard required for bulk emulsion explosives manufacturing.

Other environmental benefits are delivered by reducing heavy vehicle movements through local communities and thereby minimising the carbon emissions they cause.

In the EMEA region, Cyclo™ units are currently installed across several customer sites in Africa. Elsewhere, there are installations in Asia, Oceania, and Latin America, with a version to suit arctic conditions also being developed for Canada, China, and Mongolia.

Thus, Cyclo™ is an example of how the company is constantly looking for ways to reduce the carbon footprint of its customers whilst creating value for stakeholders.

“Orica’s premium emulsifier technology enhances the quality and stability of bulk explosives whilst significantly reducing the carbon footprint of production processes, showcasing our commitment to sustainability,” Morales affirms.

ADVANCING SAFETY

Rapid technological advancements that are reshaping the mining and infrastructure landscape are also propelling the industry towards safer practices.

New technologies are transforming safety in the mining industry by reducing human exposure to hazardous conditions, monitoring geotechnical challenges, and enhancing precision in operations.

Orica, whose approach begins with ensuring it conducts business responsibly and prioritising the safety of people, customers, and communities, helps to improve safety and productivity with smart technologies such as WebGen™ and Avatel™.

The world’s first truly wireless initiating system, WebGen™ was launched by Orica in early 2017 and completely eliminates the need for downlines and connecting wires in surface mining.

Underground, the system communicates through rocks, air, and water to initiate blasts safely and reliably, removing people from harm’s way, and enables new mining methods and blasting techniques to increase productivity and reduce blasting costs.

“WebGen™ allows for remote blasting, eliminating the need for workers to enter dangerous zones,” notes Morales.

Avatel™, meanwhile, is a semi-automated charging solution that eliminates the need to handle initiating systems or manually load blast holes.

The first-of-its-kind innovation enables a single operator to prepare the development face and complete the entire charging cycle from within the safety of an enclosed roll-over protective structure (ROPS) and falling object protective structure (FOPS) cabin.

Thus, Avatel™ represents a step change in safe and productive development charging through advanced mechanisation, automation, and digitalisation.

As well as improving accuracy in blast execution, the technology reduces the exposure of workers to hazardous environments.

“Avatel™ enhances underground mining safety by combining precision with automation, minimising human involvement in high-risk areas,” Morales elaborates.

ORACLE EMEA PARTNERS