Renowned for its state-of-the-art solutions in the nuclear power industry, Framatome Ltd supports the UK in achieving its net zero targets. CEO, Ian Henderson, shines a light on the evolving landscape of electricity sources.

LEADERS IN ENERGY AND INNOVATION

In the 1940s, UK scientists were at the forefront of nuclear energy development, and the country saw the world’s first commercial-scale nuclear power reactor by the end

of 1956.

Fast forward to the 1990s, Sizewell B opened, and nuclear energy contributed to approximately 25 percent of the country’s total annual electricity production.

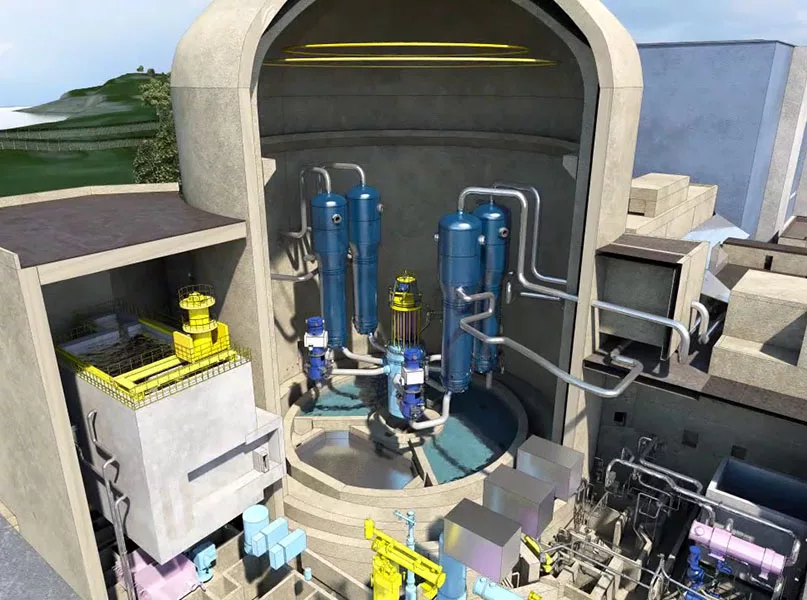

Today, the UK government has ambitious plans to increase the use of nuclear power for electricity production. At Hinkley Point Power Station in Bridgewater, Somerset, two new nuclear reactors are being built, the first in a new generation of nuclear power stations in the UK, providing zero-carbon electricity for around six million homes.

In Suffolk, meanwhile, the government recently announced a new scheme which will unlock billions of pounds to support the building of the Sizewell C nuclear power station.

Small modular nuclear reactors (SMRs) also offer opportunities for the UK’s nuclear sector, which have potential breakthroughs for nuclear power as they can be built into modular pieces in factories and assembled rapidly on-site, thus creating economies of scale.

The technologies developed and mastered by Framatome Ltd (Framatome) adapt perfectly to light-water SMRs. They also enable the development of a sovereign supply source for VVER reactors and are preferable in the domain of advanced modular reactors (AMRs) with a variety of different concepts and fuel designs.

This ongoing development bodes well for Framatome, who specialises in designing, constructing, and providing equipment, services, and fuel for nuclear power plants.

“The nuclear industry is an extremely exciting space to work in and undergoing a huge expansion that looks set to continue in the coming years,” introduces Ian Henderson, CEO of Framatome.

The boom in business is evidenced by the organisation’s recruitment drive to boost its capacity by adding 10,000 engineers, a significant investment that underscores Framatome’s commitment to the nuclear power sector and confidence in its growth potential.

“Energy security is vital to the UK and Europe, and the goal is to reduce household costs. The UK’s civil nuclear roadmap paves the way to achieve net zero objectives by 2050, and Framatome is a huge part of this, perfectly aligning with the government’s vision of a dynamic and growing sector,” Henderson sets out.

Framatome’s activities focus on several main areas, including nuclear power plant design, nuclear steam supply systems (NSSS), fuel and components design and manufacturing, chemical and process engineering, instrumentation and control (I&C) systems integration, nuclear reactor operation and maintenance, and cybersecurity.

Established in France over 65 years ago as Framatome SAS, the UK entity has had a presence for over 20 years and is a subsidiary of the EDF Group.

After recently acquiring Efinor and BHR Group in the UK, the organisation also provides solutions to the defence, space, and healthcare sectors.

“Energy security is vital to the UK and Europe, and the goal is to reduce household costs. The UK’s civil nuclear roadmap paves the way to achieve net zero objectives by 2050, and Framatome is a huge part of this”

Ian Henderson, CEO, Framatome Ltd

STATE-OF-THE-ART SOLUTIONS

The nuclear industry requires demanding, multidisciplinary, and highly technical expertise, which is encompassed by Framatome.

Its solutions and state-of-the-art technologies range from the design and supply of nuclear equipment, powering operations, and maintenance and engineering services to the design, development, and fabrication of high-performance advanced fuels for all types of light water reactors belonging to electricity utilities.

For the design and service engineering speciality, Framatome offers customers a wide range of bespoke specialisations.

“Our engineers are specialised in the design of NSSS and their principal items of equipment, mobilising expertise in a variety of areas such as metallurgy, chemistry, mechanics, welding, neutronics, fluid mechanics, and thermal hydraulics, as well as nuclear safety, reliability, and scientific calculation,” Henderson explains.

Furthermore, the organisation manufactures heavy and mobile components for nuclear reactors, also supplying nuclear propulsion equipment for the French defence sector.

Framatome has a highly skilled manufacturing base and supplies customers with high-quality, cutting-edge technologies which are deployed in forging, welding, machining, heat treatment, inspection, and testing.

Moreover, to operate a nuclear power plant, the I&C system provides precise, reliable, and safe control. The company designs, manufactures, installs, and maintains advanced nuclear I&C solutions to ensure the safety, availability, and reliability of each plant.

“Our Centre of Excellence in Cranfield, Bedfordshire is where we design complex structures and test rigs, carry out analysis of engineering problems using finite element analysis (FEA) and computational fluid dynamics (CFD) software, and utilise our experience and our developed capability,” Henderson affirms.

A POWER PLANT PRESENCE

Framatome has a sizable footprint in the UK, with more than 400 employees across various locations.

On a global scale, the organisation acts as the original equipment manufacturer (OEM) for 92 nuclear power plants, providing specialised knowledge to over 350 nuclear plants worldwide and managing a workforce of over 19,000 experts.

“We are supplying manufacturing solutions, technology, services, and nuclear fuel to Sizewell B and Hinkley Point C (HPC) both directly and through our work within EPR Engineering Ltd, and we will be replicating this for Sizewell C,” informs Henderson.

In its capacity as the reactor’s OEM, Framatome has invested in and created local facilities and on-site support for the construction of HPC.

A dedicated global delivery team has trained and developed employees and has vast experience on international nuclear projects, such as Flamanville 3 in France, Okiluto 3 in Finland, and Taishan in China.

“HPC’s heaviest equipment, the Framatome steam generators, are being transported from our facility in France, and the first 520 tonne (t) generator has safely arrived at the construction site,” Henderson reports.

“These 25m generators, which will convert nuclear reactor heat into steam to power the world’s largest turbines, travelled by river, sea, and road from our plant in Saint-Marcel.”

Contracts are already in place for post-nuclear operations, and the company is actively recruiting engineers to support the commissioning of the project and future nuclear operations.

“We are closely collaborating with Sizewell C Ltd to maximise replication benefits for the Sizewell C plant based on our HPC experience and proven design. Framatome will deliver the two nuclear heat production systems, replicating the design from HPC and overseeing their supply to commissioning,” he confirms.

Framatome will also provide the plant with safety instrumentation and control systems with a long-term fuel supply agreement in place, under which it will fabricate the fuel needed to power the two reactors.

Indeed, Sizewell C will accommodate two EPRs, enabling it to produce 3.2 gigawatts (GW) of low-carbon electricity, powering approximately six million homes for 60 years.

“Our goal is to establish a reliable foundation that will sustain and advance the future of the nuclear industry in the UK”

Ian Henderson, CEO, Framatome Ltd

GENERATING THE FUTURE

Framatome has expanded rapidly in recent years in line with the UK energy sector and associated industries.

As one of the first major economies to enact a new zero emissions law, the organisation is helping the UK achieve its 2050 targets by constructing new EPRs and supporting the maintenance and long-term operations of existing plants.

“As we offer advanced solutions to our customers in the UK nuclear sector, chemical, process, and defence industries, the growth in engineering and technology requires a highly skilled and diverse workforce.

“For these reasons, we provide comprehensive technical training and partner with leading universities to nurture local talent through collaborative nuclear science, technology, and engineering programmes,” prides Henderson.

Substantial investment in Framatome has enabled the organisation to provide engineering services across various sectors.

It also has extensive expertise in the design and manufacture of nuclear fuel and fuel assemblies, zirconium production, fuel element manufacturing, and related fuel services.

“We are considering expanding our fuel fabrication operations in the UK to accommodate the new generation of nuclear reactors. The facility could be a scalable UK fuel fabrication facility to support all types of nuclear technology,” he divulges.

“Nuclear energy is a clean source of electricity, which produces nearly zero carbon dioxide or other greenhouse gas (GHG) emissions and avoids the usual pollutants associated with burning fossil fuels. It therefore complements renewable energy sources and contributes to the stability of electricity grids.”

To prepare its people as the world transitions to a clean energy future, Framatome is committed to local skills.

The company’s engineers are developing various solutions and technologies to support the evolution of nuclear energy systems.

Due to the increasing demand for more flexible power generation, Framatome is also promoting the global advancement of hybrid energy systems through SMRs, which offer a low-carbon alternative to ageing fossil-fuelled power plants.

In 2021 and 2022, meanwhile, Framatome completed several acquisitions that led to its proliferation. This strategic move has positioned the organisation to address the challenges and opportunities of guiding the UK towards a sustainable and brighter tomorrow in the energy sector.

“Our goal is to establish a reliable foundation that will sustain and advance the future of the nuclear industry in the UK,” Henderson concludes.