We speak to Dr. Wilfred Barkhuizen, CEO of thyssenkrupp Industrial Solutions Middle East & Africa, about the company’s delivery of industry plants and systems across countries, and its expanding digitalisation in the field.

DIGITAL MINING EVOLUTION

“Compared to other areas in the world, I would say the African continent is probably one of the most challenging environments, but also probably has the most untapped and unexplored minerals deposits globally,” begins Dr. Wilfred Barkhuizen, CEO of thyssenkrupp Industrial Solutions Middle East & Africa (thyssenkrupp). “The long-term outlook for Africa is also very promising, considering the battery minerals and hydrogen potential of the continent.”

It is fair to say that the African mining sector is an exciting place to operate within. thyssenkrupp Industrial Solutions is a business segment of thyssenkrupp, an international group of companies comprising largely independent industrial and technology businesses.

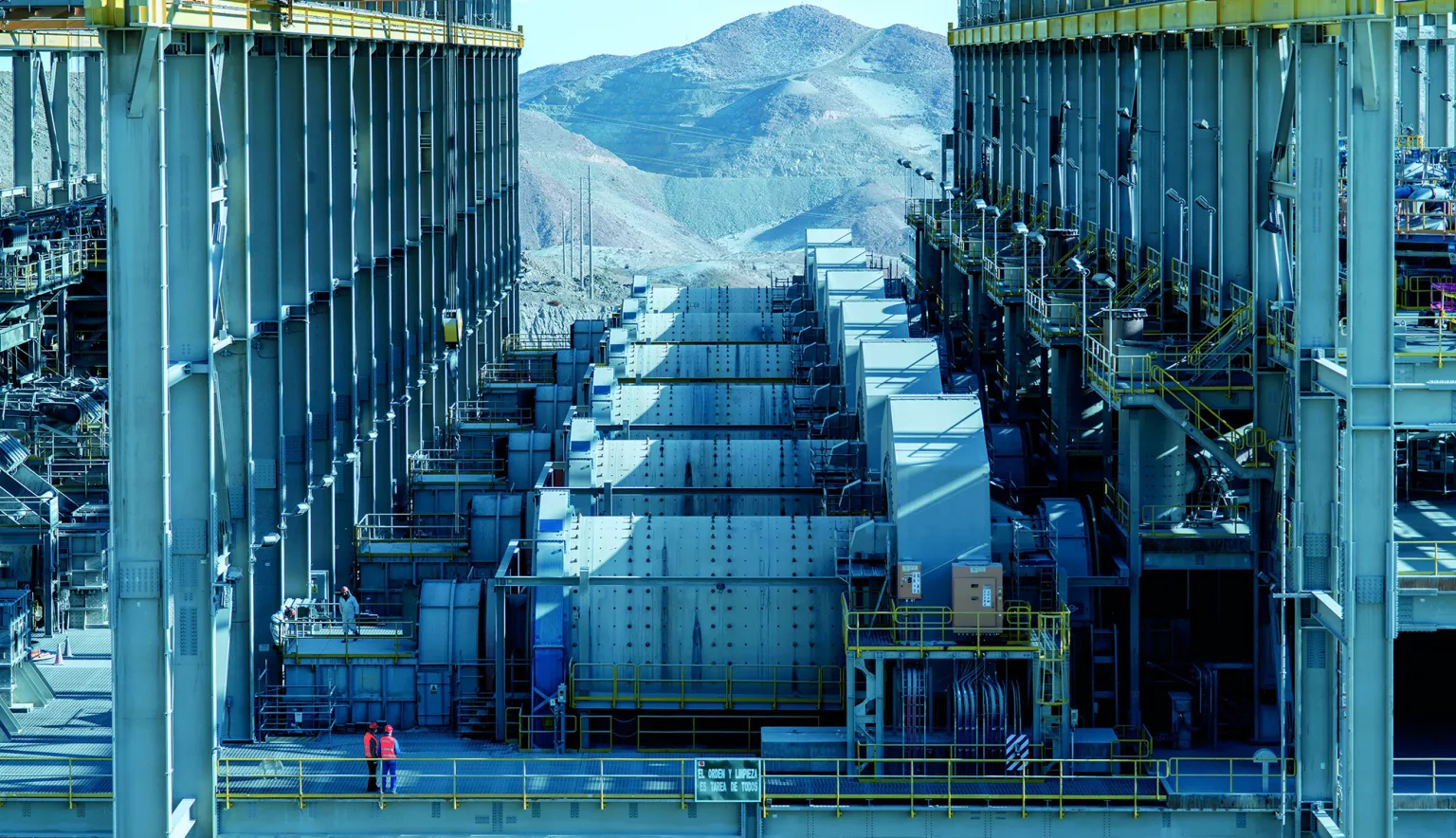

In collaboration with its customers, thyssenkrupp Industrial Solutions is a leading partner for the engineering, construction and service of industrial plants and systems. Top-quality solutions and a global network ensure the delivery of efficiency, reliability and sustainability over the entire life cycle of each project, and set benchmarks in terms of value added and resource-friendly technologies.

“We deliver such projects across multiple countries, including Saudi Arabia, the UAE, South Africa, Egypt and Morocco,” Barkhuizen informs us. “Our mining business, with around 3,500 employees, is distributed with offices around the globe in all the major mining hubs.

“We partner with our clients who range from the largest mining companies in the world to the junior miners. Our product focus is on comminution (crushing and grinding), materials handling and providing state of the art digitalisation and automation solutions. Our products are supported by our international service network, including 12 service centres around the globe with very unique manufacturing and machining capabilities.”

“We have a strong focus on digitalisation and sustainable solutions”

Dr. Wilfred Barkhuizen, CEO, thyssenkrupp Industrial Solutions Middle East & Africa

LEADING WITH TECHNOLOGY

For thyssenkrupp Mining Technologies, digitalisation offers great potential for improving process efficiency and competitiveness in engineering, on both the construction site and in services. New and innovative solutions such as digital twins or Building Information Modelling (BIM) are much in demand and are elements of operation that place companies ahead of the competition in the space.

“We offer products with future technology through our skilled and experienced teams today, and alongside continuous service support as close as possible to our client’s locations,” Barkhuizen tells us. “In most instances our products are market leaders, and therefore are normally part of the critical process streams in minerals processing plants which also demands the highest level of agility from our service teams.

“We have a strong focus on digitalisation and sustainable solutions, and our In Pit Crushing and Conveying (IPCC) systems and innovative application of High Pressure Grinding Rolls (HPGR) technology in process design, are just some of the examples to showcase our green technology.”

Along with the engineering and process know-how of the company’s engineers and its digital competencies, thyssenkrupp Mining Technologies combines decades of experience from the worldwide installation of thousands of plants and machines with state-of-the-art data-based solutions. To increase the availability and productivity of plants and processes the main levers are identified to offer customers suitable solutions. This is what the company calls ‘Digitalised Expertise’.

“Being a technology driven company, we aim to continuously improve our products through technological advances and incorporating experience gained from our numerous global installations,” Barkhuizen affirms. “At the top of this list is also our new Eccentric Rolls Crusher (ERC®) and HPGR Pro. The advances on these products will have dramatic effects on plant throughput and performance and will open the opportunities for innovative process flow sheet design, due to the capabilities of these products. Together with the digitalisation and automation products, there is an exciting outlook for the ‘mine of the future’.”

“The power of true efficiency”

thyssenkrupp Industrial Solutions Middle East & AfricaEXPANSION AND DEVELOPMENT FOR THYSSENKRUPP

As part of its plan to grow its services, thyssenkrupp has focused investment on the aforementioned digital side of service, but also its multiple sites and facilities, in order to move forward as the optimum choice for industrial plant and system projects in the mining space.

“The main service hub for Africa was established in 2008 in South Africa, to service the large population of HPGRs within the continent,” Barkhuizen explains. “During the last decade, our service centre in Chloorkop has continuously grown and expanded its capabilities to service and refurbish our complete product range.

“In November of 2018 we opened our training academy; a location at which we develop exceptional skills in Africa. We aim to produce the best artisans for the continent, we are registered with merSETA, and following a 36-month training period related to grinding, crushing and materials handling equipment, our apprentices qualify as fitters, turner machinists and boilermakers. We are very proud of them all.”

On top of this, thyssenkrupp opened service outposts in Mozambique, Zambia and Ghana, highlighting the company’s ambitions and aims for growth in the places where its services are most in demand.

“For the Middle East and Africa region we have also established a service centre in Turkey,” Barkhuizen informs us. “Backed with high-quality products and customised technological solutions, the Turkish service centre enabled us to meet our customers where they are.

“With commitment and highly skilled personnel, this service centre is also capable to manufacture and service a wide range of thyssenkrupp products, and we already see that this is producing a positive impact for both us and the customers in the region.”

FACILITATING CHANGE

Moving forward, thyssenkrupp is targeting a growth strategy in the next few years as a result of many opportunities presenting themselves in the market, as well as pursuing innovative approaches to seeing company services engage closely with clients.

“There is definitely a focus on our digitalisation and automation products as well,” Barkhuizen says. “This is with a specific goal to show clients that they can optimise plant performance and lower operating costs through this optimisation.”