Executives from Inflite Engineering discuss what sets the company apart from its competitors and how the firm is operating in a post-COVID-19 world.

OVERCOMING DISRUPTION

Aviation has experienced a tumultuous 18 months.

The industry has stared disruption square in the face amidst COVID-19 which meant unprecedented disruption and interruption to a sector that was relatively buoyant prior to March 2020. However, fast forward to September 2021 and positivity is slowly returning to the space.

“We’re on the cusp of recovery, though many risks remain,” explains Martin Reynolds, Group Finance Director at Inflite Engineering. “It is fair to say that the industry has been badly impacted and aviation manufacturing grounded to a halt almost overnight – it will likely take a number of years to get up to full capacity again.”

Reynolds works at Inflite Engineering, a part of the wider Inflite Group which includes manufacturing and maintenance in Bishops Stortford, Stansted, Chelmsford, Southend, Farnborough and its Jet Centre and FBO at Stansted.

Founded in 1983, Inflite has become of the most important major suppliers to the aerospace industry and centres on four core divisions which each offer knowledge and expertise that are second to none in their respective sectors.

Reynolds has been with the organisation since November 2014. Having led a career primarily in aerospace and defence, Reynolds has previously worked at BAE Systems and Raytheon. “As anyone can tell you that’s worked in aviation, it’s a very interesting sector to work in and support,” he explains. “For me, it was a find. I never knew the company was here on my doorstep all this time.”

He sits alongside William Stephens, CEO at Inflite Engineering. With a family background steeped in aviation and engineering heritage, there was no doubt over which direction Stephens’ career path would take. “Inflite is a family business and always has been,” he tells us. “It was my dad that began the business, and it was his dad that originally established a company called Victoria Welding based in Stratford. Throughout school, I always knew where I wanted to end up and I prepared myself to come into the business.”

And from there, Stephens served in a number of different roles. Having begun on the shop floor, he worked in assembly, manual milling, production control, commercial and procurement, before moving into a management role and eventually the CEO position. “This business has been my life and is all I’ve ever wanted to do. My passion is to further grow and develop the business to become a key supplier of precision components,” he affirms.

GOING GREENER

COVID-19’s impact not only caused operations to halt overnight and propel people and businesses into chaos, it meant that sustainability initiatives were suspended too.

“Sustainability is a huge topic in the industry at the moment, but it seems a lot of green initiatives were put on hold by the OEMs as a cost saving exercise,” adds Stephens.

“However, the industry is currently in an exciting but challenging moment. It is highly competitive in Europe and the competition remains fierce. There’s a lot to look forward to and a lot of change ahead over the next 10-15 years with regard to green aircraft.”

Many organisations are embracing a greener approach as the world becomes more environmentally friendly. For Inflite Engineering, sustainability is taken seriously but acknowledges the aviation industry isn’t as far ahead as it should be.

“It’s certainly an important focus area but a little bit behind,” explains Stephens. “What we can do, we certainly do. We’re compliant with all regulations and stay current with our chemical and waste disposal. We’ve invested lots of money to ensure we’re recycling our machine tool coolant and are around 80 percent down on the usage and procurement of coolant. This means that less is lost among the metal chippings made by the manufacturing process. We’re also looking at installing solar panels in order to bring down our energy usage. This is not just an environment benefit but a cost benefit to the company.”

“This business has been my life and is all I’ve ever wanted to do”

William Stephens, CEO, Inflite Engineering

SETTING THE STANDARD

Inflite Engineering undertakes a significant amount of work that others in the sector cannot do. Stephens believes this acts as a real competitive advantage for his firm.

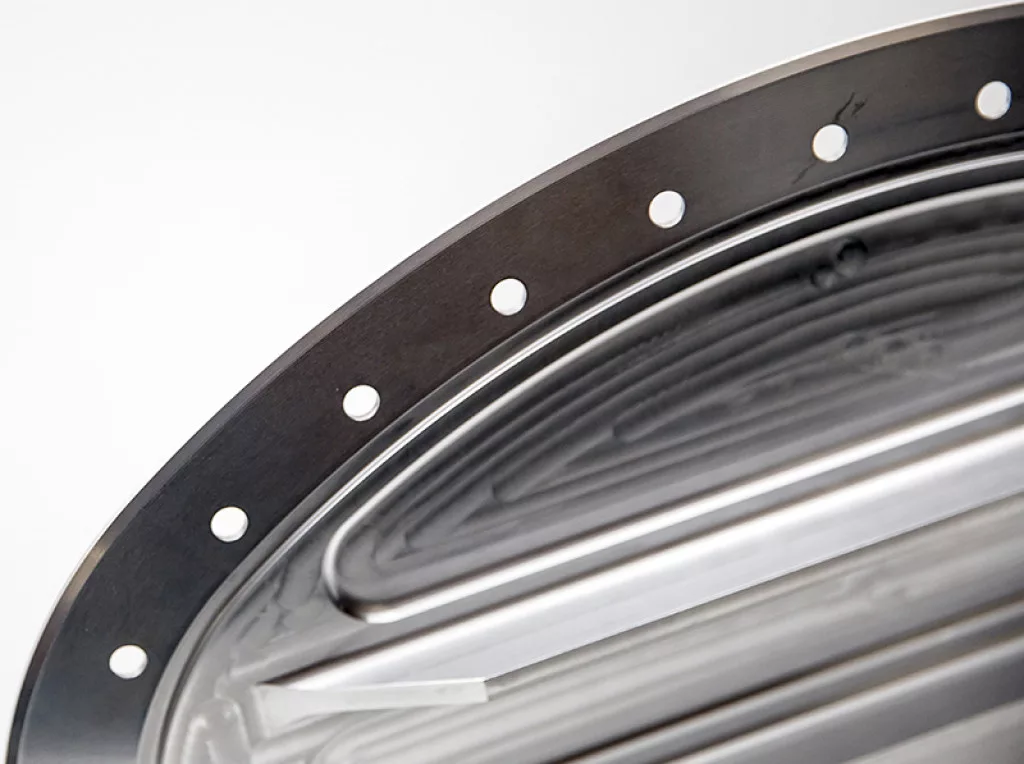

“The challenge that interest us is taking the concept and working with OEMs to solve the engineering solutions,” explains Stephens. “Inflite Engineering undertakes a lot of work that other people don’t want because they can’t do it. We’re very good at taking a complicated part and figuring out the engineering and how to manufacture it and make it repeatable.

We’re someone who will take on a risky part but nurse it in-house to find the engineering solution and find a way to make it work.

“We don’t design an end product. This will mean the innovation will be focused on the process of manufacture.”

Inflite Engineering is selective over the partners it chooses to work within its supply chain.

The reason for this, according to Stephens, is the importance of quality. “You’re only as good as your supply chain,” he affirms. “We monitor this closely and always make sure that our suppliers are well-chosen and controlled. We try to keep our circle small and tight, so we only really go out into the open marketplace if we’re finding particular problem parts.

It’s about how reactive and accommodating we are. Customer relations are important and it’s certainly a target area for us.”

Despite dealing with primarily a UK only supplier base, Stephens explains that you can never fully avoid the impact of COVID-19. “This is because a lot of material mills are in America, China and India so getting materials are always going to be a risk,” he says. “However, on the whole we’ve been fortunate. We always try and deal with local companies where we can make our own collections and stay local for fuel efficiency and more economical to deal with UK suppliers. It’s all about de-risking the supply chain.”

The organisation is at the point of implementing a new ERP system and undergoing an IT server restructure as it seeks to accelerate its digital transformation. “We see this as a crucial part of achieving efficiency,” says Reynolds. “We’re seeing a considerable emphasis on an IT restructure, in addition to investing in new machines to stay up-to-date with the competition. The current technology that we’re looking at is primarily IT and infrastructure based as we try and get the most out of the equipment that we have. That technology is hopefully going to help us make a better, stronger business long-term.”

Talent management is another critical component for all successful businesses. In order to ensure long-term success in the market, recruiting and retaining quality staff is essential. But Stephens concedes that it is challenging, particularly in today’s world. “It’s not easy at the moment and in manufacturing, it’s even more difficult,” he stresses. “There are very few places where you can cherry pick from in the area. This has meant that we focus on apprenticeships and finding people who are interested in coming into this line of work. We have a highly skilled workforce with lots of experience primed for teaching younger guys how to do it. It’s so important that we give people the training they need to learn new skills and progress their career.”

“The key for us is to survive in our current form and to grow from there”

Martin Reynolds, Group Finance Director, Inflite Engineering

LOOKING AHEAD POSITIVELY

Moving forward, the market remains uncertain as it is unclear how COVID-19 will continue to impact operations moving into 2022. Reynolds believes this makes predicting the future challenging.

“We are beginning to experience some sort of recovery but there remains a question over how long it will continue to disrupt the supply chain,” explains Reynolds. “As a result, what are the knock-on impacts of that? Inflation is a risk, but will that translate into wage inflation and higher prices for customers which will put pressure on us in the market? These are things we need to manage as best as we can. As a business, we are looking at expansion and seeking growth but this must be undertaken as and when economic conditions support this. We’re looking at doing different things for existing customers and looking at new customers outside of aviation and defence. The key for us is to survive in our current form and to grow from there.”

In the past, Stephens believes that Inflite Engineering hasn’t promoted itself enough to make others aware of its presence. However, he is keen to ensure this mentality shifts.

“We’ve always relied on our current customers and the people that know us but it’s now time to get ourselves out there and let people know what we can offer and the solutions we can provide,” he explains. “It’s a competitive marketplace especially now on the defence side with civil manufacturing being at an all-time low. The priority is to sell ourselves and reach new customers while keeping our head above the water and improving internally. We want to come out of 2021 looking positively ahead to 2022.