Having built up a formidable reputation since beginning operations in Romania in 1953, bearings manufacturer URB Group continues to innovate and explore new ideas.

THE KING OF BEARINGS

“Years ago, when I was in high school, I had already chosen to be an engineer. This was not an easy choice, and it was not an easy target to reach, because the university exam was very difficult with 500,000 people competing for 30,000 places.

“But I chose engineering as a way of life, which I saw as discovering and bringing alive new ideas, and I made it a passion.”

Little was going to stop Dogan Gures from pursuing a career in engineering.

He passed the exam with flying colours, finishing in the top 100 and securing a place at the best engineering school in his home country – the Boğaziçi University in Istanbul, Turkey.

Having backed his degree up with a master’s in engineering management, Gures’s career has seen him gain valuable industry experience in managing investments, setting up new factories, developing technological products, and overseeing production processes.

This included setting up six factories in Romania, the key moment coming in 2017 when he decided to join bearings manufacturer Rulmenti S.A. Barlad, commonly known as URB Group, as CEO.

“When the company I was working for at the time decided to make new investments in Russia, it wanted me to move over there to manage it,” Gures recalls.

“I resisted it and left because I wanted to stay in Romania and continue my career in a management position in the field of engineering. And the opportunity to serve Rulmenti and its affiliated companies as CEO, which produce URB bearings in Romania, was the perfect career choice for me.”

The company began operations in 1953 in the Romanian city of Bârlad, today employing around 1,400 people with additional production facilities in Turkey (home of the firm’s major shareholder BERA Holding) and India.

It is renowned for the design, production, sales and service of different types of bearings and is a major supplier to the global automotive industry, operating a distributor network in more than 40 countries including Germany, the UK, Italy, Benelux, France, Spain, Ireland, Greece, Poland, Bulgaria, Serbia, Ukraine, Turkey, USA, South Africa, Brazil, Egypt, India, Korea, Taiwan, Thailand, Singapore, Vietnam, and the UAE.

Major products include radial ball bearings, cylindrical roller bearings, spherical roller bearings, thrust ball bearings, thrust cylindrical roller bearings and tapered roller bearings, all well-known for their precision and reliability and produced in accordance with ISO and DIN standards.

Critical to URB Group’s ongoing standing in the sector? For Gures, it is all about human capital.

“Our human resource base has tremendous experience and engineering knowledge gained over many years,” he says. “Many of our city’s people are associated with our factory and working here is a proud legacy that passes from one generation to the next – it is a natural result to thrive in such an environment.

“We are continuing to increase the value of our brand in our sector by maintaining this advantageous situation, which is provided to us by our valuable human presence. This is our most important asset. We therefore believe in lifelong education and will continue offering institutional training and university-supported training collaborations for the younger generations.”

AHEAD OF THE CURVE

These bright sparks are responsible for driving URB Group’s busy research and development programme, activities which ensure the company remains one step ahead in the bearings industry.

Here, the team has been busy on a number of new and existing product enhancements, Gures pointing to a project being carried out in partnership with customers focussing on ceramic coating for insulating bearings.

The Group CEO also highlights work on a new spherical roller bearing. These contain steel cages within the outer diameter and provide several improvements and benefits.

Among the main features are high performance materials, low residual austenitic content, heat treatment process for dimensional stability in operation up to 150 degrees Celsius, improved cinematics, optimised rolling surfaces made on performance machines, increased thermal reference speed, higher load capacity than standard bearings and longer service life.

“In order to keep our customers loyal and open new bearing markets, our research and development department is extremely active in seeking out now solutions and testing new ideas,” Gures adds. “R&D is the first step for any process ending in technological innovation, and innovation is the key for beating the competition.

“Being stable in the top ranked places in the industry is only possible with continuous R&D investments and will ultimately make us more reputable as a company. If our company image is superior to our competitors’, then this will lead to our products being preferred, even if they are priced higher in many cases.”

R&D activity also concentrates on internal processes with a view to enhancing the production process.

Gures cites ongoing research into machine tools which can produce bearings up to a metre in diameter, as well as collaborations with the Gheorghe Asachi Technical University of Iaşi on the development of more durable bearings.

“The aim here is to implement these new technologies for the processing of bearing rings and rollers,” Gures continues. “For example, we are investing the replacement of classical grinding operations with hard turning and deep rolling operations.

“Experimental research has shown that by applying these new process techniques, the life of the bearing against fatigue can be improved by a factor of two or more. Once tests are complete, implementation may require investments in equipment and machinery.”

POWERED BY TECHNOLOGY

Indeed, URB Group is not afraid to invest in the latest equipment to give itself an extra competitive advantage.

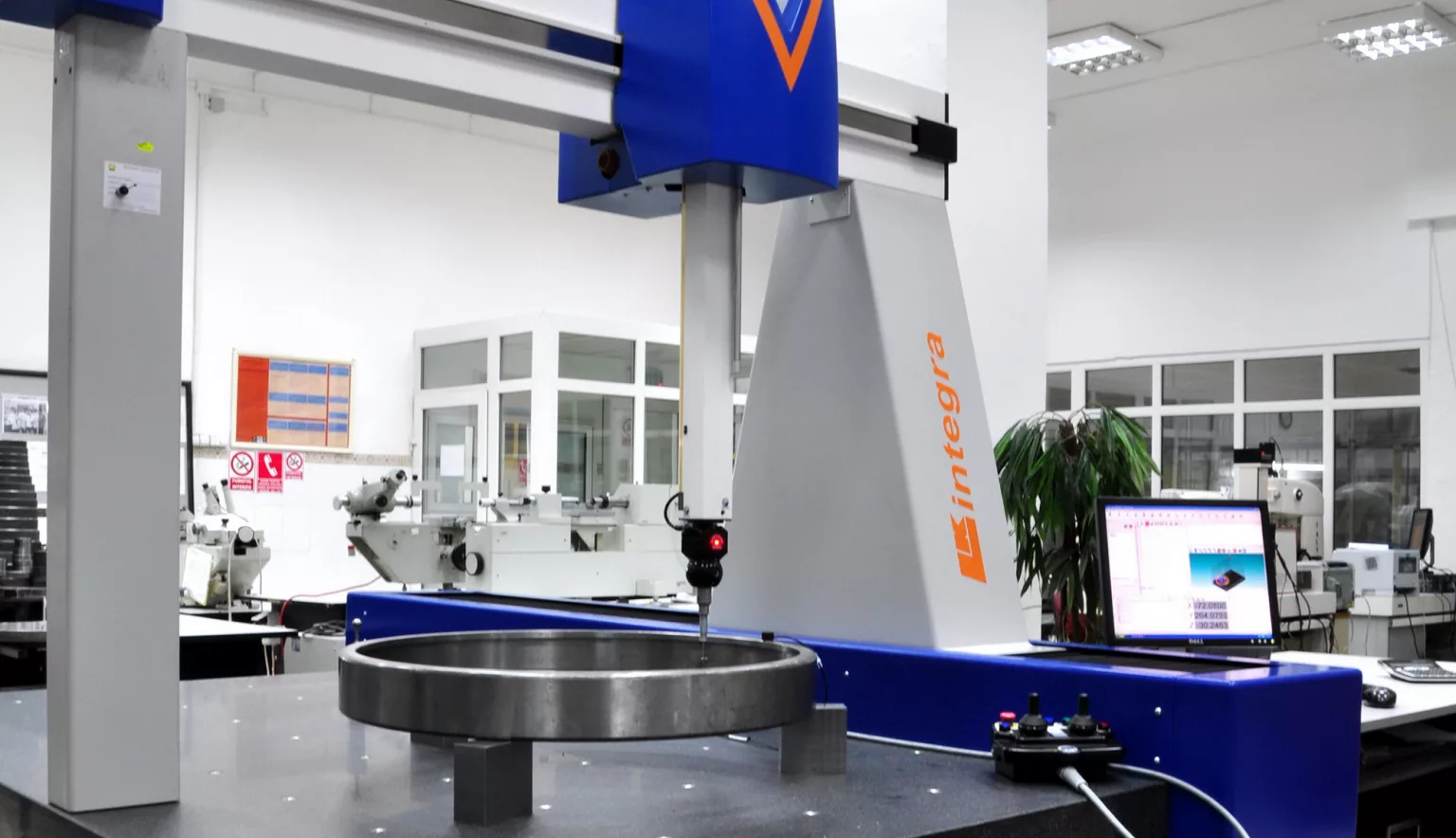

The company has a dedicated testing laboratory to qualify products internally and test their credentials before presenting them to the market, the lab equipped with Ansys software in order to simulate the potential behaviour of the products in different situations.

Testing occurs at every stage of the process using various technologies from leading suppliers, equipment which is staffed by certified operators who are routinely trained in order to keep up to speed.

“Our laboratories inspect the quality of raw materials with Quantodesk equipment, which checks the chemical composition of the material in question,” Gures says, explaining the various levels of testing a bearing will go through.

“After heat treatment, a new diffractometer X-ray assesses the structure. For the final inspection of the bearing rings and rollers, new equipment was acquired for non-destructive ultrasonic checking – the TTPS Echograph manufactured by KARL DEUTSCH and what we called eddy tests.

“The ultrasonic testing equipment is automatic, ensures a high productivity, and provides high accuracy non-destructive measurements of the product, and eddy tests have capability to identify internal micro-fractures.”

The bearings themselves are produced using laser marking methods which are adapted to suit exact client specifications, while new grinding machines from Japan and South Korea have also graced the production line.

Importantly, such investments in product and process development are determined by an integrated management approach and integrated management system certified to ISO 9001, IATF 16949, ISO/TS 22163, ISO 14001 and ISO 45001 standards.

“We continuously act to perfect processes and invest in modernising our machinery and equipment in order to keep our focus on protection of employees, improved speed, productivity, efficiency, sustainability and product quality,” Gures states.

“Investing in new technologies of course involves a certain amount of expense, but it provides greater savings in the long term.”

And it is the longer term which concerns the Group CEO as he brings the conversation to a close.

Decades of reputation building and savvy investment in employees, new locations and state-of-the-art technology have placed URB Group in a position of relative strength during what is an extremely challenging business environment created by the outbreak of COVID-19.

It leaves Gures upbeat despite the uncertainty which lies ahead. He concludes: “In a quirk of history, we do this interview with you at a time when the world is going through both a health crisis and an economic depression due to coronavirus. Many companies are experiencing difficulties in this difficult situation.

“We had predicted that this year would be a troubled year and we have also developed measures to counter it. As we continue our service this year, we will overcome adversity with these measures and enter the new era even stronger.

“Thanks to the technological tradition established by our company for almost 70 years, URB will always be known as one of the main characters of this sector, serving customers all over the world.”